Shell Mold Process

- 1 Step

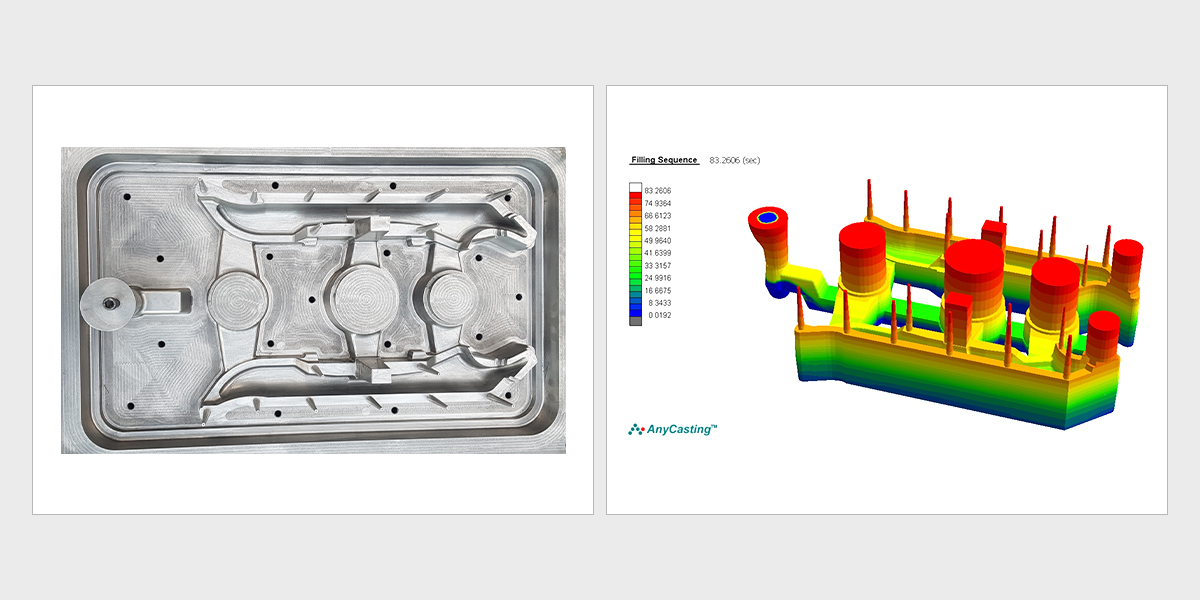

- Design Mold Design, Foundry Plan Design, Foundry Simulation

- 2 Step

- Pattern MakingHeat resin coated sand (RCS) directly or indirectly in a mold to make pattern.

- 3 Step

- Molding and AssemblingWork to assemble shell molds made through thermal hardening and bonding method.

- 4 Step

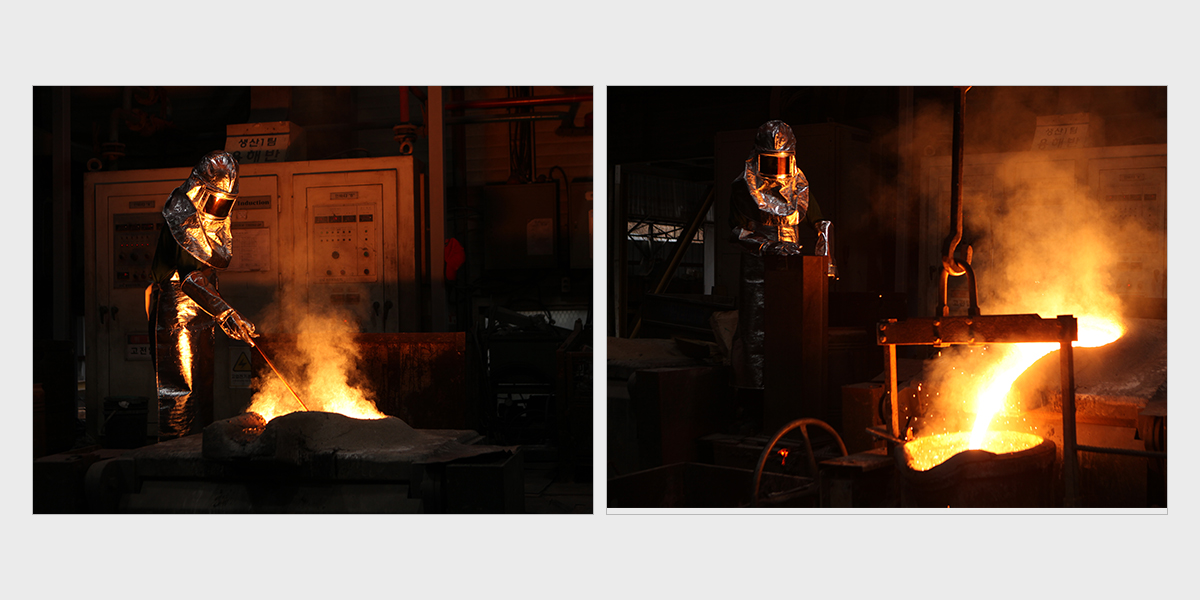

- Melting and TappingMelt raw materials of metal and combine to composition of each material At this time, confirm if the combination conforms to a target component through the collection of the component specimen. If it conforms, check the temperature to pour molten metal in a mold and move it to a ladle.

- 5 Step

- PouringPour in the cast assembled in the ladle at a target temperature. Molten metal we can pour is minimum 400kg to maximum 3,500kg.

- 6 Step

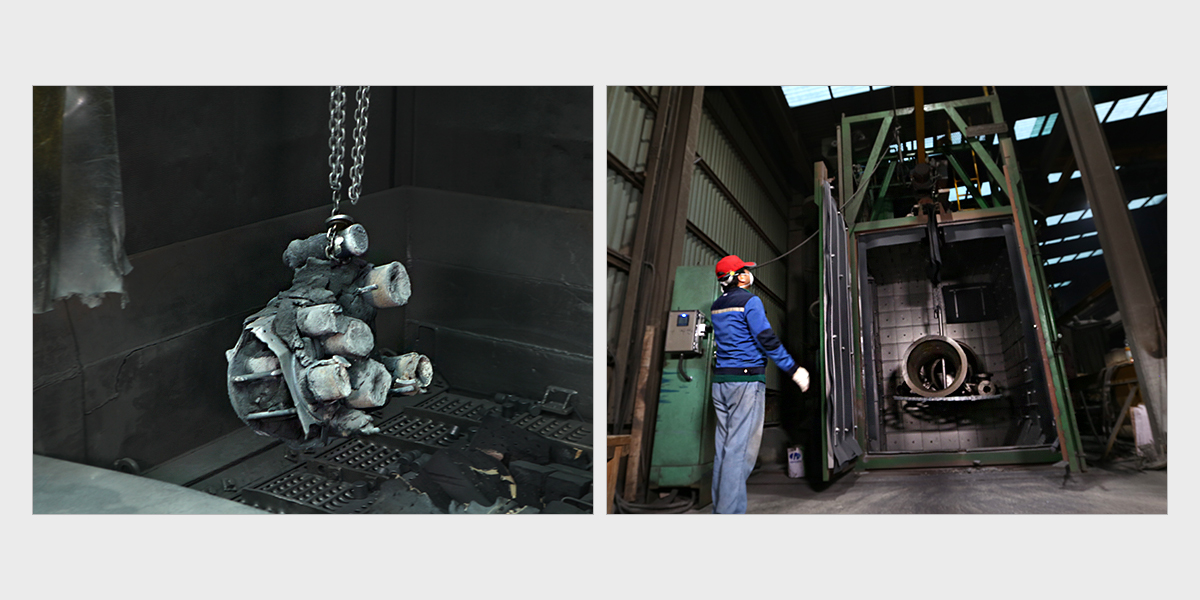

- Shakeout and Shot BlastingStakeout: Cool down the poured product completely and separate the product from the mold Shot Blasting: Blast the surface to separate half finished product from remained scale layer

- 7 Step

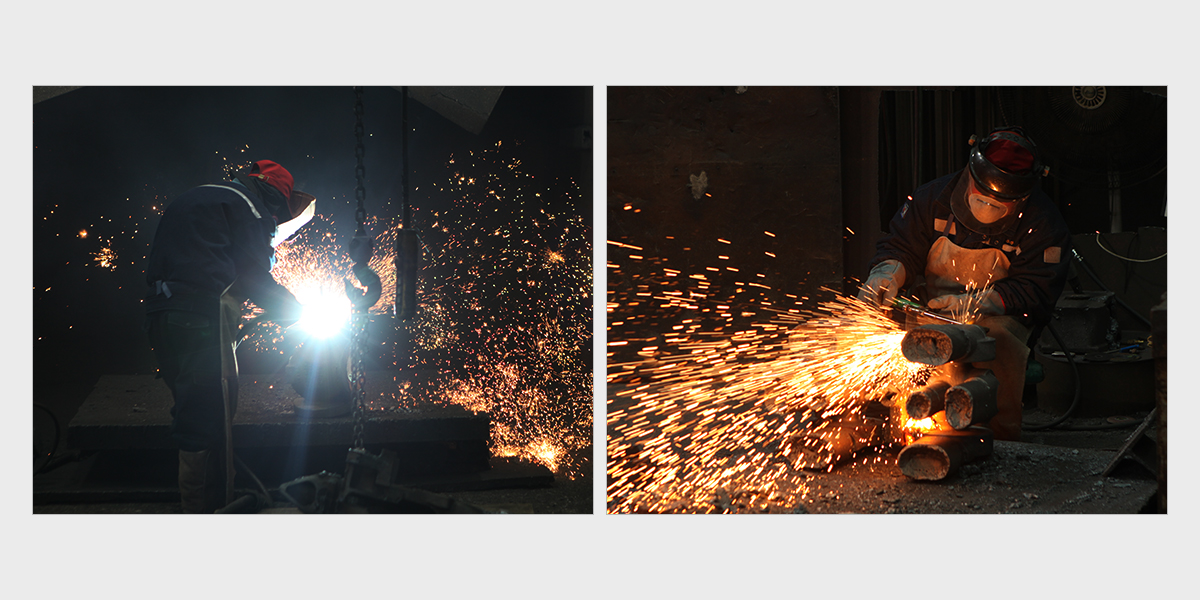

- Shaping (Cutting and Gouging)Cutting of feeder and inlet to complete the shape of the product. If necessary, carry out the welding repair.

- 8 Step

- Heat TreatmentNecessary heat treatment to meet the property of materials of each product and the demand of customer.

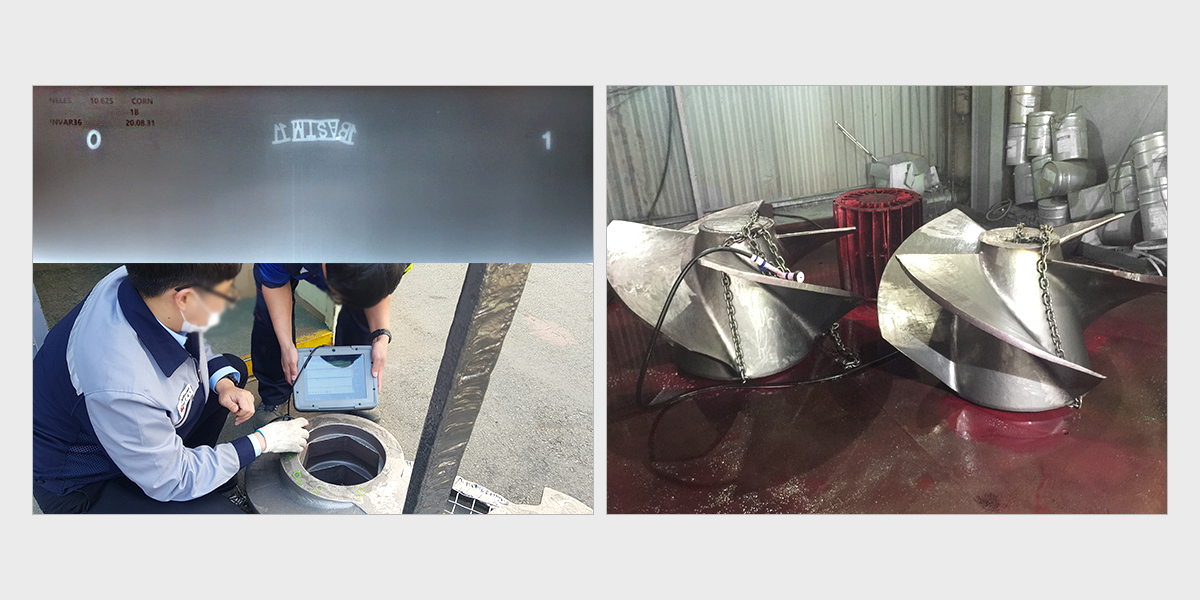

- 9 Step

- InspectionImplement a non-destructive test to meet the quality required by the customer.

- 10 Step

- Shot Blasting before ShippingImplement a shot blasting to clean the surface of the product before shipping.

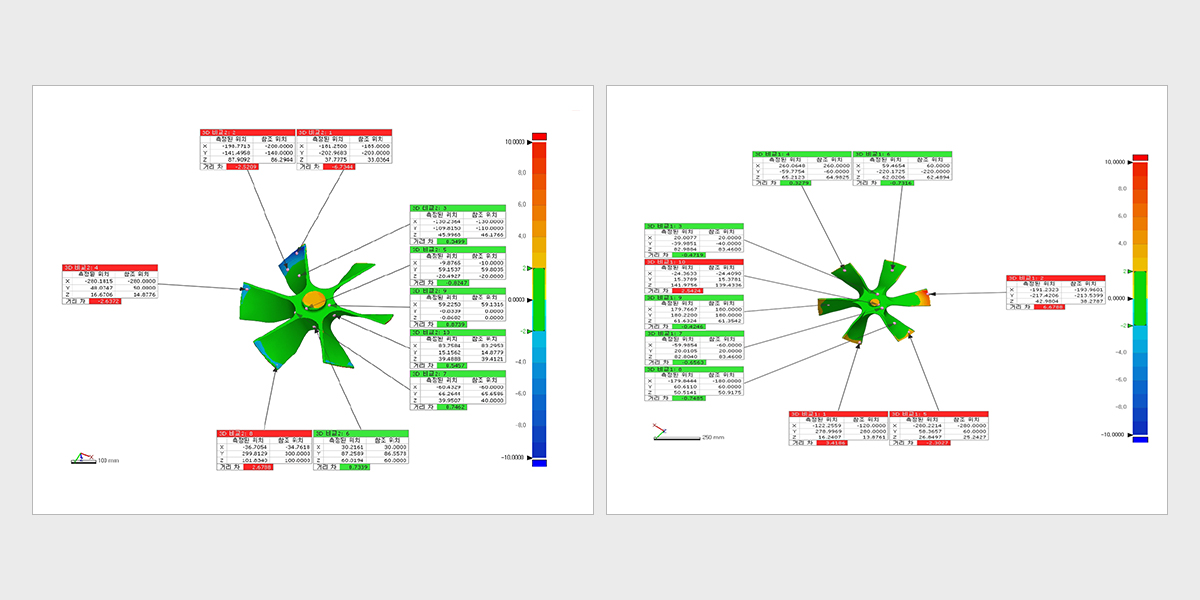

- 11 Step

- Shipping InspectionImplement a final inspection on measurement before shipping, and a visual inspection on the surface.

- 12 Step

- DeliveryWe have delivered satisfactory projects globally as well as in Korea in range of order quantity and packaging requirements from customers.